Skills Empowerment in Kenya’s Extractives Sector: Base Titanium impacting youth through the apprentice programme.

Institution: Base Titanium

Base Titanium (“Base”) is the owner and operator of Kenya’s first large-scale modern mining project, the Kwale Mine. It represents 65% of Kenya’s total mineral output value. The Kwale Mine is creating significant opportunities for economic development – through a local employment programme and procurement of goods and services from local vendors. As a recognised Vision 2030 Flagship Project, Base Titanium works closely with the Government of Kenya to promote further investment in developing the sector.

Base’s Training and Development (T&D) programme is a key component of its overall philosophy designed to deliver on commitments to maximise opportunities and project benefits to local communities and furthermore enhance the employability of young Kenyans.

Base has collaborated with amongst others, the National Industrial Training Authority (“NITA”) in Mombasa, Technical University of Mombasa (TUM), county government of Kwale, Kenya Red cross, ICDL Africa, Kenya Youth Employment & Opportunities Project (KYEOP), Strathmore university, and Association of Women in Energy and Extractives in Kenya (AWIEK) to implement the programme.

The Base Apprenticeship Programme is targeted at youth and is structured to link practical industry needs with theoretical training. The programme consists of 16 weeks of theory at the learning institution and 36 weeks of hands on training in the industry.

The local community who are directly affected by the operations of the mine, are able to apply to the programme according to selection criteria. The selection process is conducted with help from the community department who sensitize the local community on the programme needs and its requirements for qualification.

Organisational needs determine the technical apprentice positions advertised, hence change accordingly. The focus of the positions cut across various operations such as Electricity & Instrumentation, refrigeration & air conditioning, plant mechanics, boiler makers etc

The diagram below reflects the intake process:

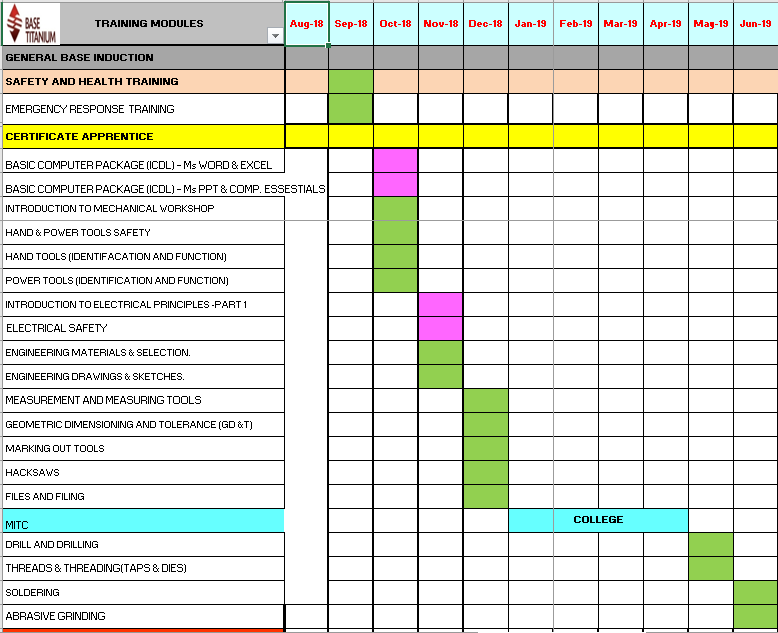

The enrolled students participate in mandatory training in areas such as communication skills, time management, computer training and workshop practice. Competency based assessments are conducted concurrently to help identify who will pursue what course as a technical speciality. To enhance skills transfer, Base Titanium employed 2 full-term technical trades trainers under Electrical and Mechanical sections . The trainers craft curriculars and learning competencies for hands on training to complement the theory training. The students are split into two groups. They attend a block training for 1 week at the training centre. where they carry out practicals and graded assessments to measure their competence. After the block training they are then released to the field for further practical application. The teaching methods are classroom based, on the job training and workshop practicals which address the different types of learners.

The trades trainers were able to develop training calendars and matrixes to ensure the learning gap is also addressed on rotation.

- Base Titanium is recognised as a benchmark organization for good practice demonstrated through the apprenticeship programme. Various agencies from government have paid visits to better understand how training programmes are structured.

- Beneficiaries from the Base Apprenticeship programme have been employed in multinational organizations such as Uniliver, EABL, Burn Manufactures, Bamburi Cement and government entities such as the Ministry of Petroleum and Mining

- The diagram below reflects the absorption rate which is determined by business needs.

|

Programme |

Commence |

Total |

Male |

Female |

Absorbed |

|

Apprentice |

2014 |

78 |

59 |

19 |

30 |

Success factors/ enablers

- Capacity building for Kwale county and having readily available local talent

- Expatriate numbers are reduced from 63 people in 2012 to 22 people in 2019

- Selected participants become employed by Base

- The reputation of Base improves further amongst employees, shareholders, the community and governments

Challenges/ barriers

- Cost associate with training programmes

- Lack of skilled talent within the local community

- Low numbers of women enrolling for technical roles

- No guarantee of employment.

- Limited numbers to support all community members for training

- Skills development takes a while to see the impact

- Lack of other participating industries

MOVING FORWARD

As part of the training mandate, Base Titanium has also opened its doors to the Vocational Centres of Training and TVET institutions to attach its lecturers in the mine operations to educate them on how a modern mine runs through incorporation of new process and new technology.

Owing to the success of these programmes, Base Titanium’s training model has been replicated at its sister company Base Toliara in Madagascar. This has been done by bringing in 25 young men and women to its operation under the apprentice programme in preparation for plant commissioning in the coming years with the aim of having a ready workforce. The apprentices will be fortunate enough to be learning first hand from specialized expatriates in the different technical fields e.g. rubber lining, boiler makers, scaffolders, arc welders and HDPE experts.

RESOURCES

https://www.youtube.com/watch?v=PzbdzcyGBMw

http://basetitanium.com/careers/graduates-and-students/technical-trade-apprenticeship-programmeme

Base Toliara apprentices departure event

https://hivisasa.com/posts/industries-urged-to-support-apprentice-training-programmes

Connect with Base

Ms. Joan Kago

M +254 715 338 805

M +261 341 002 039